Touch kitchen faucet is among the best innovations in kitchen fixtures. The best element is bronze faucets are supposed to last and you won't need to remodel again for many years. Most kitchen faucets are produced of all brass because it will not corrode like other metals when coming into contact with water. It is quite crucial that you bring every aspect together by picking out the best kitchen faucet.

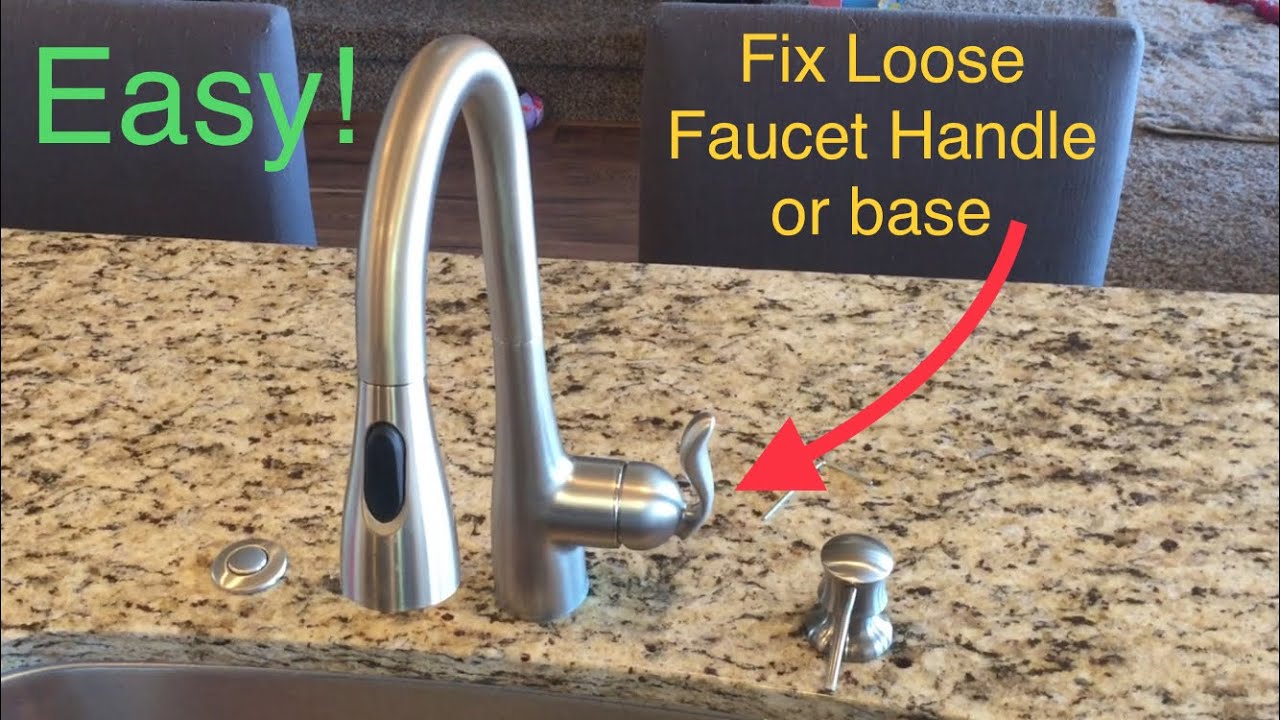

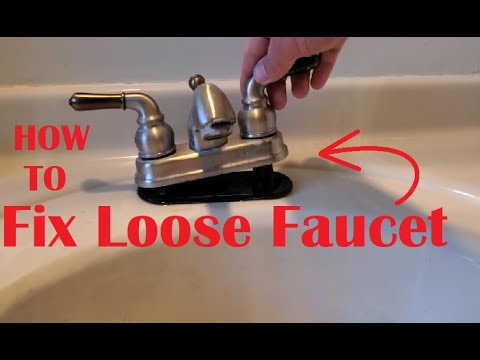

Images about How To Fix A Loose Kitchen Faucet

Right now there are additionally other methods, and this's a thing that could be great to know when you're getting acquainted with a specific kitchen faucet. People nowadays are normally very active, so they do not want to spend hours polishing or cleaning the kitchen faucets of theirs. Getting the best out of the kitchen faucet of yours is going to bring all of the features of the kitchen in concert.

How to Tighten a Kitchen Faucet? (Step-by-Step Tutorial)

Many copper finish kitchen faucets boast of a great brass construction that is known to be long lasting and extremely durable. Bring the faucet you want to have replaced on the hardware shop and they are going to advise you what type of faucet use to change the damage one. Simply see to it that you buy your white kitchen faucet from legitimate internet sites and that you never give out any personal information other than what's necessary for the transaction.

How to Fix Loose Sink Faucet

Bridge kitchen faucets can also be available from several of these brands and they're the most recent trend of kitchen decor. There are literally hundreds, if not a huge number of various kitchen faucet makes & models that we have these days. The most effective kitchen faucet could be expensive, but never go low-cost for this fixture due to the amount of use it will get.

How to Tighten a Loose Moen Kitchen Faucet Base

Although some still prefer the traditional sorts of faucet, the contemporary kitchen faucets are gaining their reputation among all the customers in the market. When you've installed one of such bridge kitchen faucets to the sinks of yours, it gets more than simply a device which is able to dispense water for you whenever you want it.

How to Tighten a Kitchen Faucet? (Step-by-Step Tutorial)

The pull-down kitchen faucets provide the sleek style you will need and also the function you desire. Additionally, you'll in addition manage to control the heat of a tub filled with warm water with such one-time handle kitchen faucets. It is an advantage to think about the design of the kitchen hence the faucet blends in seamlessly.

How to Tighten a Loose Kitchen Faucet – Moen, Delta, American Standard, Kohler

How do I tighten a loose kitchen faucet? – Home Improvement Stack

Home DIY Project: How to Tighten Kitchen Faucet Easily – Kitchen

How to Repair a Single-Handle Kitchen Faucet (DIY) Family Handyman

Loose Faucet DIY Forums

Faucet Repair : How to Repair a Loose Kitchen Faucet

Mazz™ Kitchen Sink Faucet – Loose Handle u2013 KOHLER

Why Your Kitchen Faucet Keeps Coming Loose and How to Repair It

Loose Moen kitchen faucet handle fix (3/32″ allen)

Related Posts:

- Delta Signature Pull Out Kitchen Faucet

- Moen Kitchen Faucet Cartridge 1225

- Moen Kitchen Faucet Installation Instructions

- Pure Pro Kitchen Faucet

- Kitchen Sink Faucets For Mobile Homes

- Delta Single Handle Kitchen Faucet Leaking At Base

- Best Single Handle Kitchen Faucet With Sprayer

- Delta Cassidy Kitchen Faucet Stainless

- How To Install Grohe Kitchen Faucet

- Kohler Forte Kitchen Faucet Parts Diagram